TRUMPF: Shaping the Future of the Automotive Sector & Battery Solutions

TRUMPF has a significant presence in the automotive industry through its manufacturing solutions. How do you see the future of automotive manufacturing evolving, particularly in terms of technology integration and automation?

The automotive industry stands on the brink of a profound transformation, driven by rapid advancements in technology integration and automation. TRUMPF, renowned for expertise in advanced manufacturing solutions, is poised to play a pivotal role in this revolution.

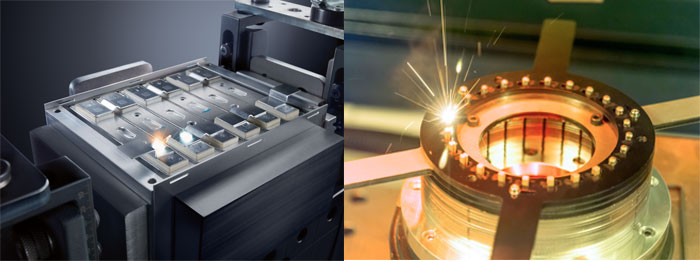

TRUMPF’s cutting-edge laser technology facilitates highly precise cutting, welding, and marking, seamlessly integrating into automated workflows. The emergence of “smart factories” will become increasingly prevalent, characterized by interconnected machines, devices, and sensors via the Internet of Things (IoT). These connected systems will provide real-time data analytics, enabling manufacturers to optimize operations, reduce downtime, and enhance efficiency.

TRUMPF’s digital solutions, such as Condition Monitoring, Quality Data Storage are instrumental in guiding manufacturers towards these intelligent, data-driven environments. Innovations in laser technology, digital manufacturing, and automation will be at the forefront of this transformation, empowering manufacturers to meet the ever escalating demands for efficiency, customization, and environmental responsibility.

The automotive sector is undergoing a transition towards electrification and autonomous driving. How is TRUMPF adapting its solutions and services to support this shift in the automotive landscape?

The transition towards rapid electrification and autonomous driving is reshaping the automotive sector, and TRUMPF is actively adapting its solutions to support this transformation. As a leader in manufacturing technology, TRUMPF is at the forefront of innovative solutions that meet the evolving needs of the automotive industry. We are playing a vital role in the automotive sector’s transition by innovative laser technology, flexible automation, and standardised digital solutions. Whether it’s in battery production, electric drivetrain, sensor technology, lightweight BIW construction, or sustainable manufacturing, TRUMPF’s innovations are helping automotive manufacturers meet the demands of this rapidly changing landscape. TRUMPF offers it worldclass Laser application labs to help customers quickly develop and validate new prototypes.

TRUMPF believes in closer to customer approach and has more than 70 locations worldwide. India subsidiary has its head office and customer experience center at Pune, with regional offices and spare part warehouses at Bengaluru and Delhi.

Quality and precision are paramount in automotive manufacturing. How does TRUMPF ensure that its laser technology and other solutions meet the stringent requirements of the automotive industry?

TRUMPF understands that quality and precision are critical to automotive manufacturing, where even the smallest deviation can impact performance, safety, and efficiency. TRUMPF adopts a comprehensive approach across our laser technology and manufacturing solutions. We integrate real-time monitoring and quality data storage into our laser processes, allowing manufacturers to track every aspect of production in real time and maintain traceability. Sensors embedded in TRUMPF machines monitor parameters such as temperature, weld depth, and laser intensity, ensuring that every part meets exact specifications. Real-time process control, automation, customization, and continuous innovation. These efforts are supported by a commitment to compliance, training, and strong customer partnerships, ensuring the highest levels of reliability and performance in automotive manufacturing.

Sustainability is becoming increasingly important in all industries, including automotive. How does TRUMPF contribute to making automotive manufacturing more sustainable, whether through energy-efficient solutions or material optimization?

Sustainability is indeed becoming a central focus in the automotive industry, and TRUMPF is contributing to this shift through a variety of innovative, energy-efficient solutions and material optimization strategies. By leveraging our advanced laser technology and smart manufacturing solutions, TRUMPF is helping automotive manufacturers reduce their environmental impact while maintaining high productivity and precision. By improving the efficiency of manufacturing processes, TRUMPF helps automotive companies reduce their overall carbon footprint. Our advanced laser and automation systems contribute to faster production times, less energy-intensive operations, and lower emissions per unit of production. TRUMPF also offers efficient laser processes for recycling electric car batteries // Battery manufacturers can reuse valuable raw materials and comply with the EU recycling quota

With the rise of electric vehicles, there’s a growing demand for lightweight materials like aluminium and composites. How does TRUMPF support automotive manufacturers in processing these materials effectively and efficiently?

Aluminium is increasingly used in electric vehicle chassis, body structures, and battery enclosures due to its lightweight nature and strength. However, it requires specialized techniques for cutting and welding due to its reflective surface and high thermal conductivity. Hot formed Panels are also extensively used in BIW of E-mobility. TRUMPF’s vast portfolio of different Laser types, are specifically designed to handle these challenges. They deliver high beam quality and precise energy control with beam shaping technology, ensuring clean, burr-free cuts and spatter / pore free welds that are crucial for automotive manufacturing. TRUMPF ensures high-quality, scalable production that supports the industry’s shift toward lighter, more energy-efficient vehicles. TRUMPF supports automotive manufacturers by providing advanced laser technologies and solutions that process these materials effectively and efficiently.

The automotive supply chain is becoming more complex and interconnected. How does TRUMPF collaborate with automotive OEMs and suppliers to optimize production processes and ensure smooth operations?

TRUMPF works closely with automotive OEMs and suppliers to optimize production processes, ensure smooth operations, and enhance overall efficiency through several key strategies: By working across multiple levels of the supply chain, TRUMPF helps ensure that all parts of the manufacturing process are aligned, from raw material processing to final assembly. TRUMPF fosters knowledge sharing and best practices between different players in the automotive ecosystem. This collaborative approach leads to continuous improvements in processes, innovation in material usage, and the application of new technologies that benefit all partners involved. In a rapidly evolving automotive industry, TRUMPF’s flexible and scalable technologies help OEMs and suppliers adapt to changes in market demands and production requirements. Whether it’s the shift toward electric vehicles or the integration of new materials, TRUMPF’s solutions ensure that manufacturers can quickly reconfigure their production lines without costly delays or downtime.

Additive manufacturing is gaining traction in the automotive sector for prototyping and production parts. How does TRUMPF’s expertise in laser technology contribute to advancing additive manufacturing capabilities for automotive applications?

TRUMPF’s expertise in laser technology plays a crucial role in advancing additive manufacturing (AM) capabilities in the automotive sector, particularly for prototyping and also for production parts. As additive manufacturing gains traction, TRUMPF’s laser solutions offer significant advantages in terms of precision, efficiency, and material flexibility. Additive manufacturing enables the use of lightweight materials, such as aluminium, titanium, and special alloys, which are essential for automotive applications aimed at reducing vehicle weight and improving energy efficiency. TRUMPF’s laser systems are optimized for processing these materials with high accuracy, enabling the production of lightweight, strong, and heat-resistant components for electric vehicles and other automotive applications. TRUMPF’s additive manufacturing solutions allow manufacturers to produce parts with internal lattice structures or other complex designs that reduce weight without sacrificing strength. This is especially beneficial for components such as brackets, housings, and structural parts, where weight reduction can significantly improve vehicle performance. TRUMPF is empowering automotive manufacturers to leverage additive manufacturing, accelerating innovation and improving the efficiency of automotive operations.

Looking ahead, what are the key opportunities and challenges that TRUMPF anticipates in serving the automotive industry, and how does the company plan to stay at the forefront of innovation and customer satisfaction in this dynamic market?

TRUMPF sees both significant opportunities and challenges in serving the evolving automotive industry, particularly as it continues to transform with the shift toward electrification, autonomous driving, and sustainable manufacturing. The transition to electric vehicles (EVs) represents a major opportunity for TRUMPF to support automotive manufacturers with its advanced laser technologies. As EV production ramps up, there is an increasing need for lightweight materials, battery components, and efficient production processes. TRUMPF’s laser solutions for cutting, welding, and joining materials like aluminium, hot formed BIW panels and composites are perfectly suited for the production of lightweight structures and battery systems. The shift toward digital manufacturing and Industry 4.0 also provides an opportunity for TRUMPF to lead the way with its Condition Monitoring, Quality Data Storage, enabling data-driven decision-making, process optimization, traceability, and real-time monitoring.