TruMould – A pioneer in precision injection moulding solutions

Automotive Injection Molding Overseas Company in USA

The AUTO MONITOR presents an exclusive interview with Prateek Mittal, Founder of TruMould, an on-demand custom plastic injection mould manufacturer. Known for delivering precision-engineered components, TruMould leverages technology and expertise to help manufacturers navigate the challenges of today’s competitive market. In this insightful discussion, Prateek Mittal shares the company’s journey, key innovations, and vision for the future of automotive injection moulding.

The Indian automotive sector is witnessing a rapid shift towards localization and advanced manufacturing. What do you think are the biggest challenges and opportunities for domestic manufacturers in this evolving landscape?

The Indian tooling sector still has a long way to go to meet the stringent demands of global automotive companies. A poor-quality tool can have massive consequences, far beyond its initial cost, as it directly impacts production efficiency, product quality, and potential sales losses for the customer.

To bridge this gap, the industry must adopt a customer-first approach by focusing on:

- Strict Adherence to Timelines – Delivering on time is non-negotiable.

- First-Time-Right Quality – Precision and accuracy must be ensured from the start.

- Moving Beyond Cost-Cutting – Customers prioritize reliability over marginal cost savings.

- Client Success as the Ultimate Goal – The focus should be on enabling customers to scale efficiently.

By embracing precision, reliability, and a long-term partnership mindset, Indian tooling companies can establish themselves as trusted suppliers in the global automotive market.

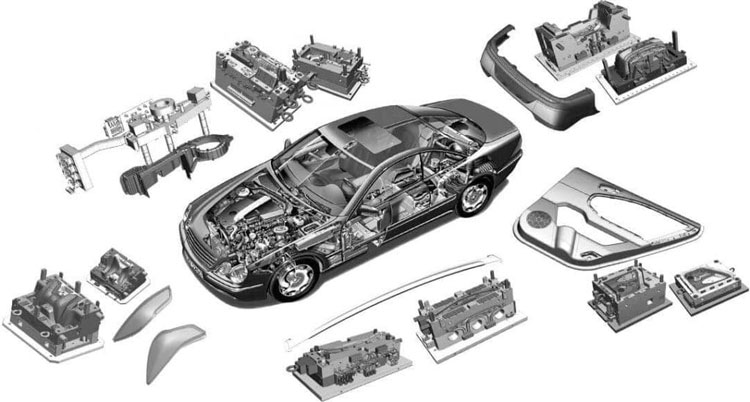

Tooling and injection molding play a critical role in automotive component manufacturing. What advancements in these areas are helping automakers achieve better performance, cost efficiency, and sustainability?

Injection molding and tooling are often the biggest bottlenecks in automotive manufacturing, particularly in mold-making and part approval, which can significantly delay new car launches. Traditionally, this process takes around nine months, slowing down innovation and market entry.

At Trumould, we have developed innovative solutions that reduce this cycle from nine months to just 60 days. By leveraging automation, AI-driven design optimizations, and a distributed manufacturing approach, we accelerate tooling development, testing, and approval while maintaining precision and quality.

This not only helps automakers launch vehicles faster and gain a competitive edge but also improves cost efficiency and sustainability by minimizing waste and production downtime.

Trumould has been supplying precision injection-molded components to the auto industry. How do you ensure your solutions align with the stringent quality and durability standards of automotive OEMs?

At Trumould, we maintain strict quality control to meet automotive OEM standards. Our customer dashboard provides real-time updates and transparency, ensuring no checkpoints are missed. We follow rigorous inspections, including full knitting checks, first-piece validation, and final inspection reports. Every client requirement is carefully documented and fulfilled, and we proactively solve manufacturing challenges to ensure precision and reliability in every part.

With the rise of EVs and lightweighting trends, automakers are exploring new materials and manufacturing techniques. How is the tooling and molding industry adapting to meet these evolving requirements?

With the rise of EVs and lightweighting, the tooling and molding industry must evolve to support faster, more cost-effective production. At Trumould, we have introduced Express Mould, an innovative solution that has cut mold-making time and cost by half. This not only benefits high-volume manufacturers but also enables low-volume players to scale efficiently. By making tooling more accessible, we are also helping boost Make in India, strengthening domestic manufacturing for the future.

Automation, AI-driven inspection, and predictive maintenance are becoming mainstream in automotive production. How do you see these technologies shaping the future of manufacturing in India?

At Trumould, we see automation, AI-driven inspection, and predictive maintenance as game-changers for Indian manufacturing. We have integrated these technologies into our platform, enabling real-time visibility of quality reports, process tracking, and maintenance insights. This not only saves valuable man-hours but also improves predictability and repeatability, ensuring consistent quality and efficiency for our clients. As these innovations continue to evolve, they will play a crucial role in making Indian manufacturing globally competitive.

Trumould has worked closely with leading automotive brands. Can you share a key project or innovation where your expertise in injection molding solved a major industry challenge?

At Trumould, we have completely reimagined traditional procurement through process, hardware, and software innovations. One of our biggest breakthroughs is enabling customers to procure 100 molds in parallel within just three months—something that was previously impossible in India and a key reason why manufacturers turned to China.

By streamlining and digitizing the entire mold-making process, we have significantly reduced lead times while ensuring quality and scalability. This innovation is helping the Indian automotive sector become more self-reliant and globally competitive

The recent Union Budget introduced various incentives for the auto sector and component manufacturing. In your opinion, which policies will have the most impact on companies like Trumould and the broader supply chain?

The Union Budget 2024 brings strong support for manufacturing with incentives for automation, AI, and digital adoption, which align with Trumould’s innovation-driven approach. Infrastructure investments in industrial corridors and logistics parks will improve supply chains, reducing costs and lead times. Financial support for MSMEs through credit schemes and tax benefits will help manufacturers scale efficiently. Additionally, skill development programsfocused on advanced manufacturing will address the industry’s talent gap. These policies collectively strengthen India’s position as a global manufacturing hub.