Artificial Intelligence (AI) is no longer a futuristic concept. It’s a tangible force reshaping the manufacturing industry. From enhancing quality control to predicting future trends, AI technologies are revolutionizing how products are made.

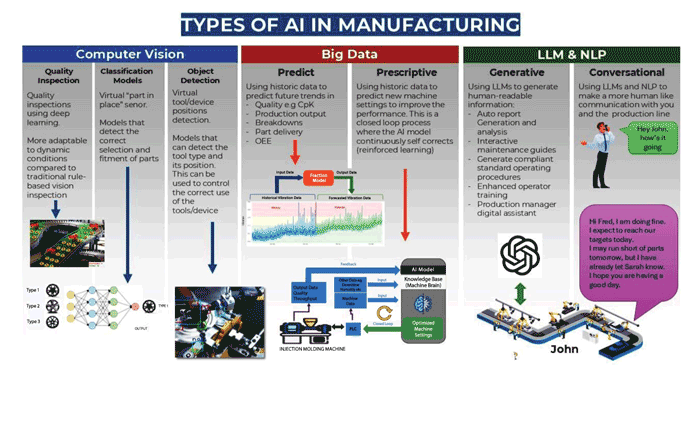

Core AI Technologies in Manufacturing:

- Quality Inspection: Deep learning is revolutionizing quality control. By learning from data, AI systems can accurately identify defects, even in complex environments. This leads to improved product reliability and flexibility in quality control processes.

- Object Classification: This technology helps identify objects, such as distinguishing between different wheel types. This ensures correct components are used in the production process.

- Object Detection: By locating objects in images or videos, object detection tracks tools and components on assembly lines. This ensures correct usage, as exemplified by electronic bolting tools that activate only in the correct position.

- Predictive Modelling: Leveraging machine learning, predictive modelling forecasts future events like demand, product quality, and equipment failures. This enables production teams to optimize processes, prevent defects, and reduce downtime.

- Prescriptive AI: Going beyond prediction, prescriptive AI recommends actions to achieve desired outcomes. By analyzing production data and predicting optimal machine settings, it continuously optimizes processes.

- Generative AI: This technology creates data and content, automating tasks and boosting creativity. Applications include report generation, troubleshooting, maintenance prediction, training improvement, design optimization, and virtual assistant roles.

- Conversational AI: Enabling human-like interaction with machines, conversational AI improves efficiency, responsiveness, and decision-making through natural language processing. This enhances collaboration between humans and machines.

ODIN Manufacturing (A Jendamark ecosystem) has emerged as a leader in leveraging real-world production challenges to develop cutting-edge Industry 4.0 solutions. With a deep understanding of the manufacturing environment, the company offers a comprehensive suite of digital tools designed to optimize production and management processes.

With solutions span a wide range of operations, from shop floor and facility management to advanced technologies like AI-assisted operator guidance, robust quality assurance systems, and immersive virtual reality training. By integrating these solutions, organizations can significantly enhance efficiency, reduce costs, and improve overall operational performance.

Odin Phantom is one of the prime solutions of ODIN Manufacturing.

ODIN Phantom: An AI vision system that virtualizes station hardware using machine learning models. By replacing hardware like sensors, buttons, and tool positioning systems, ODIN Phantom offers several benefits:

- Improved Quality: Acting as a “Google Maps” for operators, the system guides users through correct work steps, ensuring product integrity.

- Increased Flexibility: Phantom devices can be adapted to different products, enhancing production versatility.

- Reduced Training Time: Combined with ODIN Workstation, the system speeds up training for new products.

- Simplified Tool Tracking: Accurate tool tracking ensures correct usage and prevents errors.

- Cost Savings: By replacing physical hardware, ODIN Phantom reduces operational costs.

Hardware Details:

ODIN Phantom incorporates AI computer vision to guide operators through assembly processes. It connects work instructions to station equipment, validates process steps, and controls hardware for process security. Basic hardware includes barcode scanners, bolting tools, printers, and manual data entry systems. Advanced options include PLC integration, robotic stations, and tool position control.

Conclusion

AI is undeniably transforming the manufacturing landscape. By harnessing technologies and innovative solutions like ODIN Phantom, industries can achieve enhanced quality, efficiency, and flexibility. As AI continues to evolve, its impact on manufacturing will only deepen, promising a future of smarter, more productive factories.

For more details connect with us at www.jendamark.in / odinmanufacturing.jendamark.io