Crack Propagation And Development Analysis – Steering Product Optimization Using Altair® Hyperworks®

About the Customer

U-Shin India Private Limited, a subsidiary of Japanese conglomerate Minebea Mitsumi, has been committed to innovation since its inception in 1926. Renowned for its global footprint, U-Shin operates offices in Germany, Italy, Japan, and more. U-Shin specializes in the precision engineering of affordable components, including flush door handles, electrical steering columns, latches, climate control panels, and latch locks.

A preferred supplier to original equipment manufacturers (OEMs), U-Shin distinguishes itself through an unwavering focus on innovation and excellence in product engineering, serving a diverse array of customers and industries.

Altair has empowered us to develop innovative, high-performing designs by integrating simulation-driven design and optimisation capabilities into a single, userfriendly platform. Karan Thakur, Team Manager, U-Shin India Private Limited

Their Challenge

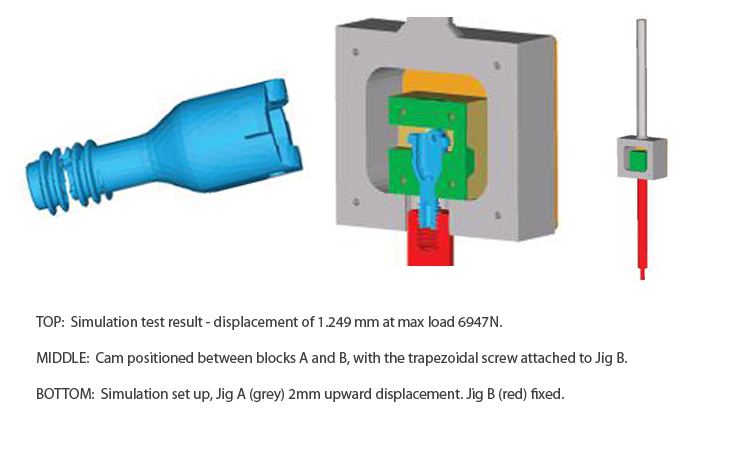

While exploring a new design of an electrical steering column lock, the U-Shin product development team discovered during testing that the product was failing due to crack propagation under a specific load. As such, the team used traditional analysis methods to make and analyze several modifications to the original design. However, the conventional analysis provided limited insights, only identifying the failure region without offering detailed information on the breaking and crack propagation process. The team needed more powerful technology to address the problem quickly and effectively.

Whether setting up simulations or seeking technical advice, the DesignTech team provides timely and effective support. This collaboration ensures smooth project executionand underscores the critical role of Altair technology and DesignTech support in product development. Abhishek Thakur – Sr. Automotive CAE Engineer, U-Shin India Private Limited

Our Solution

To reach their goals, U-Shin turned to Altair® Radioss® to run advanced crack propagation simulations. Radioss’s advanced features enabled U-Shin to analyze crack development and propagation under various loading conditions, giving them a comprehensive understanding of the part’s performance and allowing them validate its effectiveness. U-Shin further streamlined their product development process by utilizing additional Altair solutions. Altair® SimLab® proved particularly beneficial, allowing the team to quickly generate meshes while conducting analyses on repeatedly modified parts – significantly reducing pre-processing time.

Thanks to its capabilities, the Altair® HyperWorks® platform is now used more regularly in U-Shin’s product development initiatives, especially when testing critical components. The platform’s versatile, robust, and flexible capabilities ensure quality meshing, the flawless execution of finite element models, and maintain U-Shin’s high standards of complex components. Overall, U-Shin uses a variety of Altair tools software tools throughout the Altair HyperWorks platform, including Altair® Inspire™ for topology optimization; Altair® MotionView® for multibody dynamics simulations; Altair® HyperLife® for fatigue simulations; and Altair® Flux® for electromagnetic simulations. In addition, using Total Materia gives the team access to an extensive, detailed material library – which is essential for achieving seamless designs. In all, Altair HyperWorks empowers U-Shin to navigate seamlessly through every stage of the product development workflow, from pre-processing and simulation to optimization and post-processing enhancing productivity, innovation, and reaffirming its commitment to excellence in product development.

Results

The simulation results the U-Shin team gained from Altair HyperWorks fulfilled the team’s expectations and desires. The identified crack failure regions enabled decisions related to component reinforcement, while subsequent simulations confirmed the part’s improved structural integrity by comparing the enhanced areas with the original. The advanced simulations further provided accurate predictions and validations, reducing the need for multiple iterations and physical prototypes. This streamlined the development process and enhanced U-Shin’s ability to deliver robust, reliable automotive components.

The U-Shin team is enthusiastic about continuing to use Altair software for their design and product development processes, and they plan to leverage Altair HyperWorks to enhance design optimization, streamline production processes, and improve material utilization. The team finds value in the platform’s advanced simulation capabilities, as it reduces their development time and costs while maintaining the high quality and performance standards their OEM clients expect. Altair HyperWorks will continue being an integral platform in U-Shin’s pursuit of innovation and product development excellence.

To learn more, please visit altair.com/altair-hyperworks