The automotive industry is undergoing a transformative era driven by digitalization and automation. Central to this evolution is the integration of open automation ecosystems and advanced robotics solutions. Among the groundbreaking technologies reshaping the landscape is PLCnext Technology, developed by Phoenix Contact. This innovative platform is not only enhancing the efficiency of automotive production lines but also addressing critical challenges related to obsolescence, proprietary toolkits, and cybersecurity threats.

The Role of Open Automation Ecosystems in Automotive Manufacturing

Open automation ecosystems represent a paradigm shift from traditional, closed systems to more flexible, interoperable solutions. These ecosystems are characterized by their use of open standards and protocols, enabling seamless integration and communication between diverse automation components. This openness facilitates a more adaptable and scalable approach to industrial automation, crucial for the rapidly evolving automotive sector.

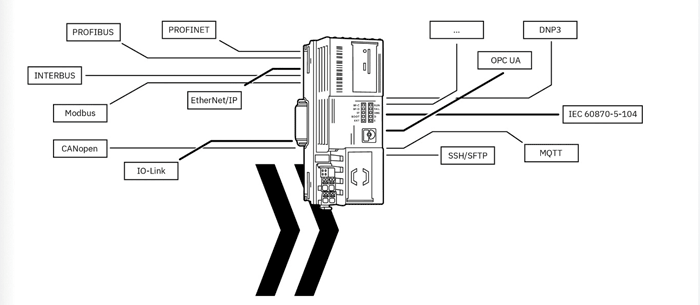

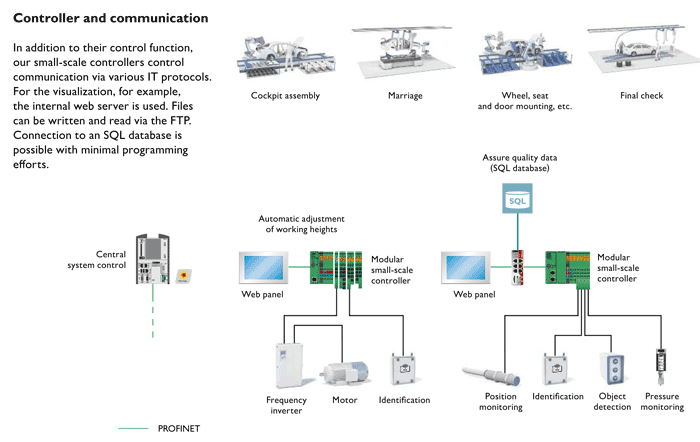

PLCnext Technology epitomizes this shift. By leveraging open standards and providing robust support for various programming languages, PLCnext allows manufacturers to integrate and control diverse automation components through a unified platform. This capability is especially beneficial in automotive production lines, where the need for synchronization between robotics, sensors, and other machinery is paramount. With PLCnext, automotive manufacturers can implement more sophisticated and adaptable automation solutions, enhancing overall production efficiency and flexibility.

Addressing Challenges in Automotive Automation

Despite the advantages of automation, the automotive industry faces several challenges that hinder the efficiency and security of production lines:

- Obsolescence of PLC Technologies: Traditional PLC systems often become obsolete as technology advances, leading to high costs for upgrades and replacements. Proprietary toolkits and fieldbus communication protocols further complicate integration with newer technologies, creating compatibility issues and limiting the lifespan of existing systems.

- 2. Cybersecurity Threats: The rise of Industry 4.0 and the increased connectivity of industrial control systems (ICS) have introduced significant cybersecurity risks. Automotive production lines are particularly vulnerable to cyber-attacks due to the critical nature of their operations and the extensive network of connected devices.

- Complexity and Integration Issues: The diverse range of proprietary technologies used in traditional PLC systems can lead to integration difficulties. This complexity often results in inefficient communication between components and higher costs for system maintenance and upgrades.

How PLCnext Technology Addresses These Challenges

PLCnext Technology provides a comprehensive solution to the challenges faced by the automotive industry through its open and secure ecosystem:

- Mitigating Obsolescence: PLCnext is designed with futureproofing in mind. Its support for open standards and interoperability ensures that it can integrate seamlessly with existing systems and new technologies. This flexibility minimizes the impact of obsolescence by allowing manufacturers to upgrade components without overhauling their entire system. The platform’s open architecture also facilitates the use of modern programming languages and development tools, reducing the dependency on proprietary solutions.

- Enhancing Cybersecurity: Security is a critical focus of PLCnext Technology. The platform incorporates advanced cybersecurity features such as secure communication protocols, access controls, and regular updates to address vulnerabilities. By adhering to international security standards such as IEC 62443, PLCnext helps protect automotive production lines from cyber threats. Its open nature also allows for continuous improvements and updates to its security features, ensuring that manufacturers can respond to emerging threats effectively.

- Simplifying Integration: PLCnext’s support for open standards and protocols simplifies the integration of various automation components. By enabling interoperability between different systems and devices, PLCnext reduces the complexity of automation solutions and lowers the costs associated with system maintenance. This streamlined integration process facilitates smoother communication between robotics, sensors, and other components, leading to more efficient and reliable production lines.

About Phoenix Contact:

The adoption of open automation ecosystems and technologies like PLCnext is revolutionizing the automotive industry by addressing key challenges related to obsolescence, cybersecurity, and integration. PLCnext’s open architecture and advanced security features empower manufacturers to create more adaptable, secure, and efficient production lines. As the automotive industry continues to embrace digitalization, technologies like PLCnext will play a crucial role in driving innovation and ensuring the resilience of automated manufacturing systems. By leveraging these advancements, automotive manufacturers can not only enhance their production capabilities but also safeguard their operations against evolving threats, paving the way for a more advanced and secure future in automotive manufacturing.

Visit : www.phoenixcontact.co.in